CAN CARRIER APPLICATOR

MODEL 2500 / 4 and 6 Pack Options / 12 and 16 Ounce Options

DESCRIPTION:

The Sawvel Model 2500 Can Carrier Applicator was designed to be an efficient and affordable option for growing breweries, with base speeds ranging from 20 to 60 cans per minute. Optional setups can reach up to 140 cans per minute. This clean, stainless steel machine’s wash-down design supports simple sanitization, and the dual-feed wheel applicator ensures consistent and positive application for popular can carriers.

PERFECT FOR:

- Breweries

- Beverage companies

- Contract packers

- Fast-growing companies

CONTAINER SIZE RANGE:

- 12 and 16 Ounce Options

- 4 and 6 Pack Options

“Our greatest challenge before we got Sawvel Automations’ can handle applicator was speed and capacity. After hand-packing all of our cans as they came off our old line, we knew we needed an upgraded system for our new 4-head Wild Goose Canning system. The Sawvel Automation capper machine didn’t disappoint. It is so slick, easy, and efficient. Ultimately, it’s made our business better by eliminating that manual capper job role so that person can focus on doing something else around the brewery because we know the Sawvel automation applicator will do the job hassle-free. Sawvel Automation managed to make a very user-friendly model that anybody could run, and they did it in a small footprint. It doesn’t take up that much space in our brewery, yet it’s probably one of the most efficient pieces of equipment we own. Set it and forget it!”

– Tom Schufman, Head Brewer

Waconia Brewing

FEATURES AND BENEFITS

BENEFITS:

- Allows for a significant increase in throughput with no additional labor costs

- Quick change times between 12 and 16 ounce can setups

- Easy to use controls and operator-friendly design

- Eliminates the need for hand application

- Set up for speeds of 20 to 60 cans per minute and capable of 140 cans per minute with minor upgrades and tuning

- Designed for 12 and 16 ounce cans

- Capable of 4 and 6 pack operation

- Compact design and footprint

- Designed for easy cleanup in wash-down/wet environment

KEY FEATURES:

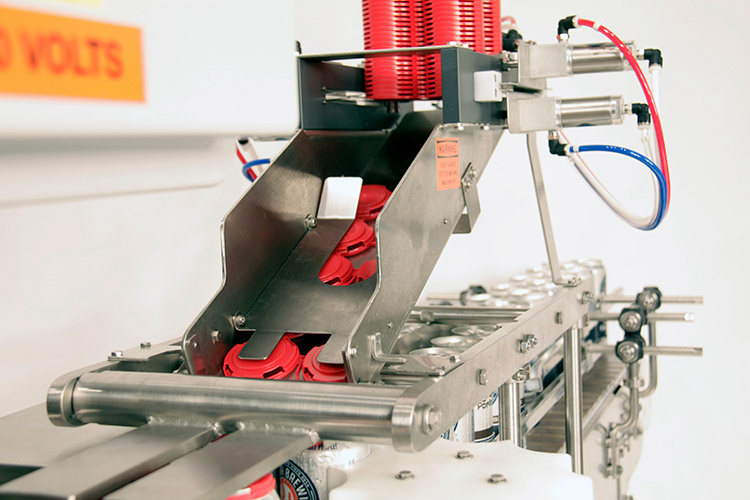

- Food-grade conveyor section with can divider supports easy side-by-side movement into handle closing assembly

- Mechanically-driven feed plates feed cans positively through the lid applicator assembly

- Automatic handle-feed supplies one handle on-demand into the applicator chute

- 304 Stainless Steel construction with some food-grade plastics

- Stainless steel leveling screws

- Simple controls: Machine Off/On, Handle Feed Off/On, Emergency Stop, Auto-stop when can supply is low

OPTIONS AVAILABLE:

- Configurations for multiple can sizes

- Configurations for multiple pack configurations

- Stainless steel caster package

- Configuration for high-speed operation

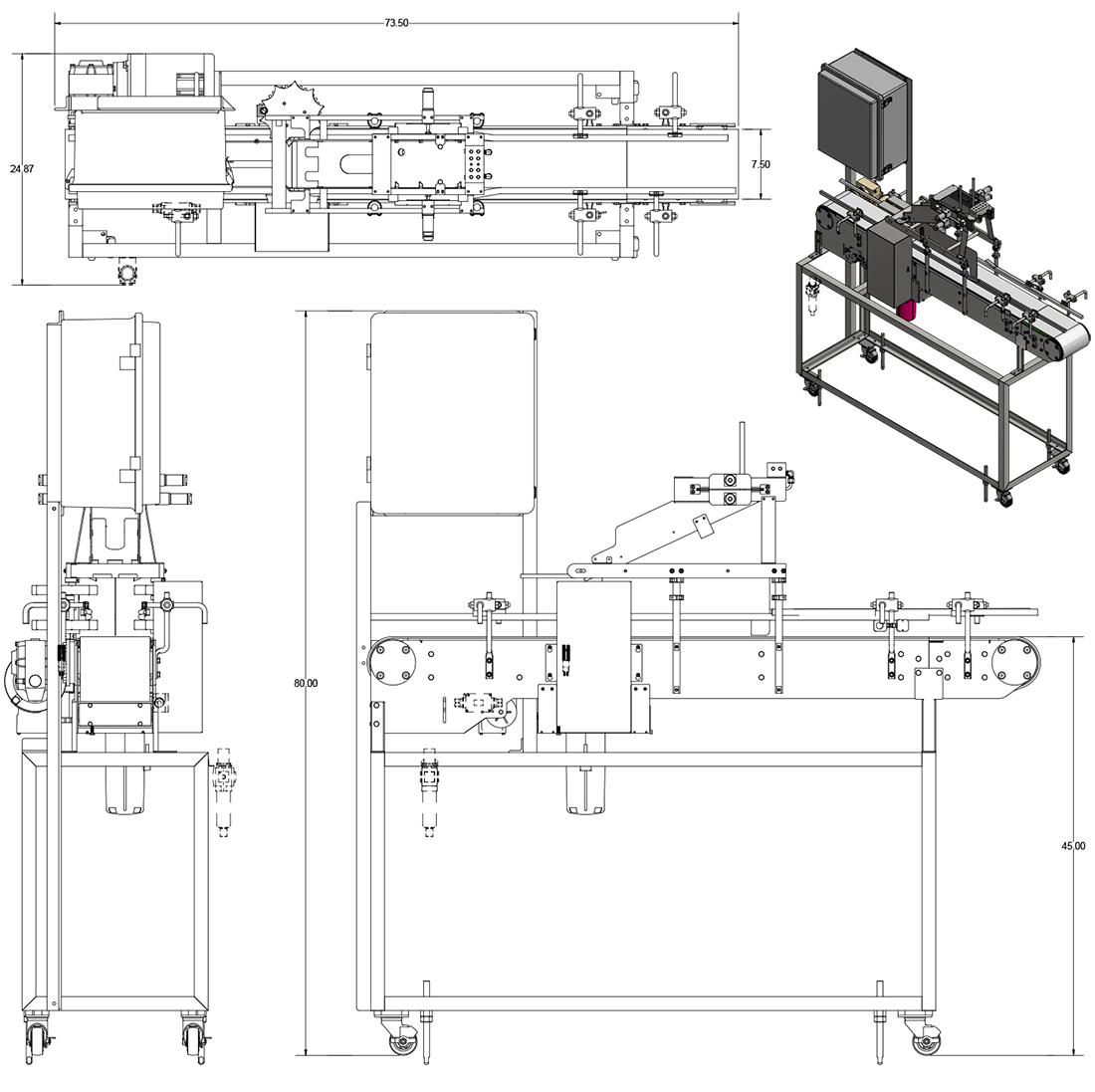

SPECIFICATIONS

AND ELEVATION DRAWING

Cans:

(211 diameter)

beverage cans

Handles:

PakTech can carriers

Air Requirements:

1 CFM at 80 PSI

Electrical Requirements:

115 Volt Single-Phase,

6 Amp

Shipping Weight:

250 pounds

Width:

25”

Length:

74”

Lead Time:

Approximately 8 weeks

Tooling Currently Available for PakTech Carriers:

QuadPak – QPCE-202-260-PCR

6PAK – 6PCE-202-260-PCR